Posted on May 20, 2012

This spring I was fed up with many issues with my current road bike. The bottom bracket made an annoying click with every pedal turn and flexed big time. The shifters wouldn’t shift to all positions. I was running 7 gear shifters (functioning as 6 gear) on an 8 speed chain. The almost 20 year old carbon/aluminum frame probably isn’t super dependable.

I became enthralled with the idea of building my own bike around a unlabeled carbon frame from China. Most of these go for <500$ and are more or less the same as name brand frames.

The definitive information source for these frames are the terrible organized but comprehensie forums at roadbikereview.com.

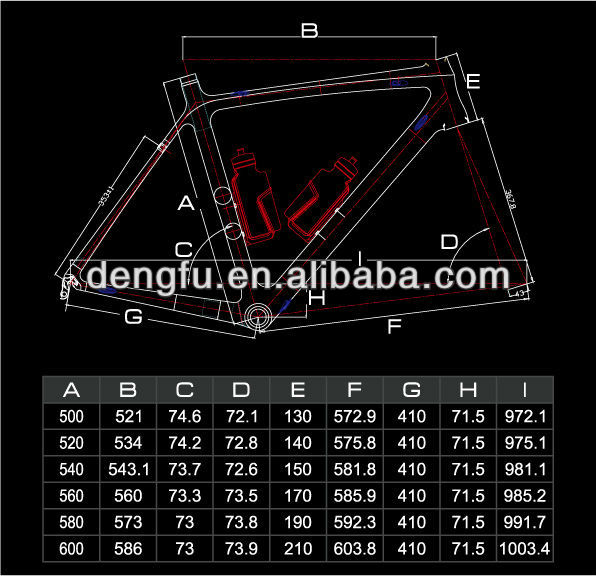

I settled on the DengFu FM029 60cm, which is the same as the very popular FM028, but with internal cable routing. ISP was only a little bit extra, I decided to go for it since I know my saddle height. I went with a Matte 3k finish. Glossy looks better, but can get scratched and dirty easily.

I was mostly concerned with durability. Carbon wasn’t an option because of expense, breakpad wear, and lack of need to race. ROL Volant had amazing reviews, and was rated for up to a 240 pound rider. Perfect!

I indulged and got RED shifters, they are excellent.

Having decided on a BB30 frame, SRAM had very few options. I found irresistable deal on a 177.5mm standard (39/53) RED crankset. The 177.5mm length should work well with my longer legs.

With a standard crankset, I really didn’t need an 11 tooth gear. I considered the 12-32, but decided that the disadvantages of needing a mid-range deraullier cage and having wider gear spacings weren’t worth it. The 12-28 has single tooth increments from 12-17. My final gear ratios.

The bike was put together in a single weekend. The most difficult part was installing fork crown race. This was mostly due to the fact that I didn’t have the proper crown race driver. After some tool improvisation and some very light sanding (the fit was extremely tight), it finally went together. The most time consuming and stressful part was cable cutting and routing. Measuring the correct cable length is very difficult. On top of this, extra cable length might be needed if you plan to adjust handlebar height later on.

This portion of the build was difficult as there wasn’t a cable router with the bike frame. The bare metal cable going under the bottom bracket would quickly cut through the carbon. To resolve this I removed a 1 foot segment of the inner plastic tube from excess shift cable. I used rubbing alcohol to lubricate the inner cable, and then easily removed it from the coiled metal and outer tube with pliers. I positioned the tube to cover the entire cable from the defailleur to the beginning of the internal cable section, ensuring no wear or dirt will reach the cable.